HOME > English > Solutions and Services > EMS Business Solutions

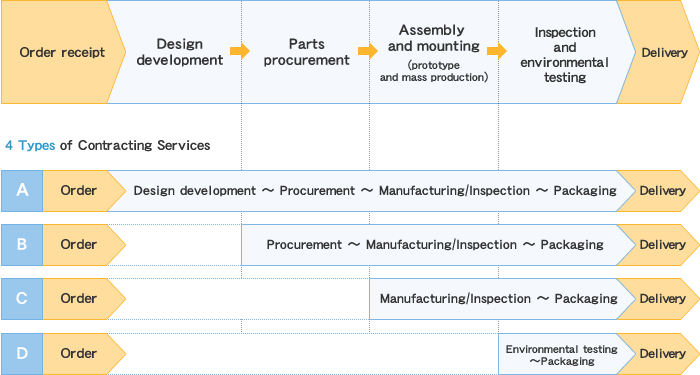

REJ is a proven company that can contract to a consistent quality in any of the following stages for your process line units, PCB assembly, SMT manufacturing, product finishing or electronic equipment buildings. We serve your needs at the highest level.

Circuit configuration, software design, architecture, printed circuit board design

Electronics parts, power supply, mechanical components, secondary material

1) Mounting of printed circuit board (leaded components and SMT), inspection (visual inspection, PCB inspection, functional testing), checker, inspection jig, rework and repair

2) Assembly, wiring, harness cable processing, wiring harness, unit inspection (wiring, insulation, electrical continuity, load, functional testing), test instruments design and repair

Vibration and temperature testing

1) SMT (small to large size): Enables mounting of CSP, BGA (0.25mm pitch), QFP (0.2mm pitch), 0603 chip, PLCC variance components (73mm IC, electrolytic capacitor, connector, coil, sensor).

2) Leaded components: Enables mounting of large capacity components such as electrolytic capacitor, cement resistance, transducer, coil and current sensor. Mounting of leaded components only (soldering bath) is also supported.

3) SMT / leaded joint PCB: Enables mounting of chip on both faces and leaded component in one surface with a dispenser, spray fluxer, and flow soldering bath.

4) Enables lead free soldering in all processes of mounting lead components in an N2 reflow soldering oven or N2 flow soldering tank.

5) BGA rework: Enables BGA mounting/unmounting, reball in a BGA rework unit.

6) Enables mounting of press fitting connector with a press machine.

7) Waterproofing PCB with conformal coating that acts to protect circuitry and components from abrasion and solvents.

8) Enables isothermal aging on PCB board or mounting board in a thermostat chamber.

1) SMT inspection

• Prevents misplacement of parts and components by fixed mount barcode scanners.

• In leaded packages like SOP and QFP, detects twist and bend in lead and removes defectives.

• Checks solder printing through the printer’s inspection function.

• Facilitates early defect detection in an assembly process and inspects BGA soldering process.

• Visual appearance test by experienced engineers: soldering, polarity, coplanarity, correct parts placement.

• In-circuit test: Electrical probe testing of PCBs for solder opens to see whether the assembly is correctly fabricated.

• Detects shorts, resistance, capacitance, coils, coplanarity of leads and other defects missed through visual check. Inspection tools can be designed as well.

• Functional testing of PCBs: Performed by checker or inspection device. Checker can be designed as well.

Built-in, assembling (screw tightening torque and soldering), wire processing, harness cabling of electrical parts, PCBs and mechanical components.

A finished unit goes through the following tests: wiring, withstand voltage, electrical startup, overload, functional testing. Design of inspection tools and instruments is supported.

Packaging design, material planning and packaging of PCBs and assembly units.

Vibration testing and temperature testing of PCBs and assembly units.

In February 2003, EU issued Directive 2002/95/EC on RoHS (Restriction of the use of certain Hazardous Substances in electrical and electronic equipment) in Electrical and Electronic Equipment.

The RoHS directive took effect in July 2006 and restricted the use of specific hazardous materials found in electrical and electronic products.

In response, REJ has been striving to tightly take action against the use of the following environmentally harmful substances: Lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE) flame retardants.

REJ has focused on the RoHS process and established lead free soldering process in our factory. Currently, we are handling SMD populated PCB assemblies in RoHS lead free process. To ensure an optimal connections, reliability testing and quality assurance plans are conducted for high quality solder joints so common soldering defects, solder materials, mounting conditions, soldering methods, procedures and mold compounds will be carefully examined.

REJ has qualified and transitioned our product line to meet the RoHS/lead free finish requirements as follows:

1. Reflow soldering process (new SMT introduced in Dec. 2014)

2. Flow soldering process (introduced in Feb. 2005)

3. Post mounting, rework and modification: Soldering robot, option, hand soldering, rework center, rework equipment (introduced in Feb. 2005)

4. Inspection process: Appearance examination equipment (introduced in Feb. 2005)

5. Nitrogen generator (reflow/flow/robot) (implemented in Feb. 2005)